Liquid Hydrogen Reading 1

Transient-state modeling and thermodynamic analysis of self-pressurization liquid hydrogen tank considering effect of vacuum mutl-layer insulation coupled with vapor-cooled shield

类别:

Insulation System; VMLI; VCS

insulation methods:

- HGMs(Hollow glass microshperes)

- MLI(multilayer insulation)

- VMLI(vaccum multilayer insulation)

- VD-MLI(varied density MLI)

- VCS(vapor-cooled shield)

Intro

大多数(VMLI-VCS性能)研究关注稳态场景,而实际低温流体储存情况涉及连续变化的温度与压力,因此瞬态研究尤为重要。

critical:

- Pressure Change

Previous research:

- Jiang et al. RANS+Lee model+fractional volume method, heat transfer and phase change, different gravitational accelerations

- Fu et al. 2-d, phase transition and pressurization process, different gravity environments

- Liu et al. 2-d, temperature and velocity distribution and pressurization

当时间尺度较长时,CFD瞬态分析不适用

Previous studies about long-term prediction for thermodynamic parameters variation ONLY consider fluid domain, no VMLI

综上,考虑了VMLI耦合VCS的瞬态CFD计算过程很少,且局限于较短时间尺度的模拟。

Definition

- Dormancy(休眠时间): 达到最大压力前的储存时间,VMLI+VCS用于延长休眠时间

- Vapor mass consumption(蒸气消耗量):VCS消耗的蒸气量

Dimensionless Parameters

- vapor consumption factor(ratio of consumption to total initial mass)

- dormancy extension factor(extension with VCS opened relative to closed)

- unit factor(efficiency of VCS)

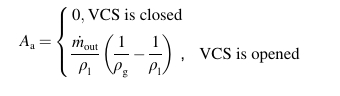

模型建立

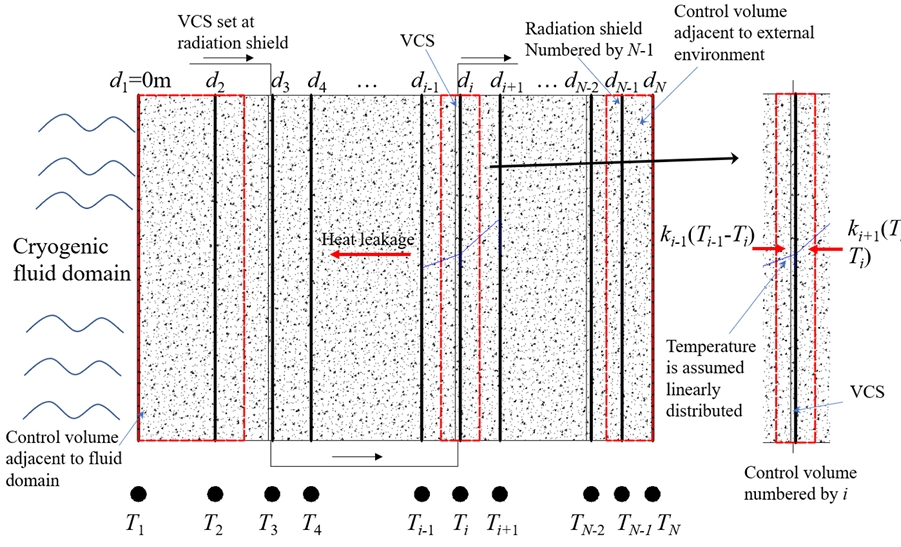

VMLI耦合VCS结构使用双层镀铝聚酯膜辐射屏,并用涤纶网格分离

假设:

- 忽略VCS中氢蒸气的动能与势能

- 初始温度与压强均匀分布

- 忽略正仲氢转化

- VCS出口温度等于辐射屏温度

- 内壁温度等于液氢温度

- VCS中忽略流阻

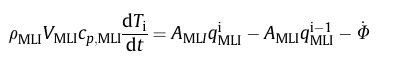

计算模型

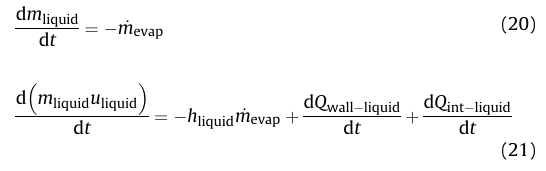

液相区传热传质模型

气、液质量分布,温度分布,压力分布

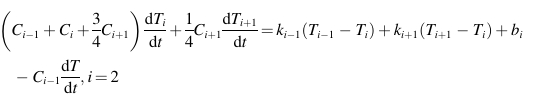

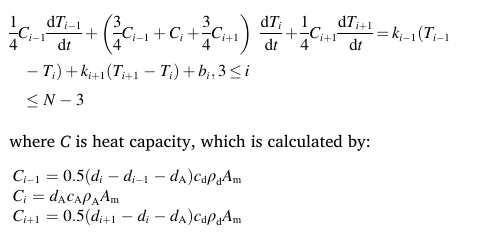

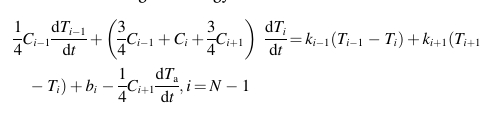

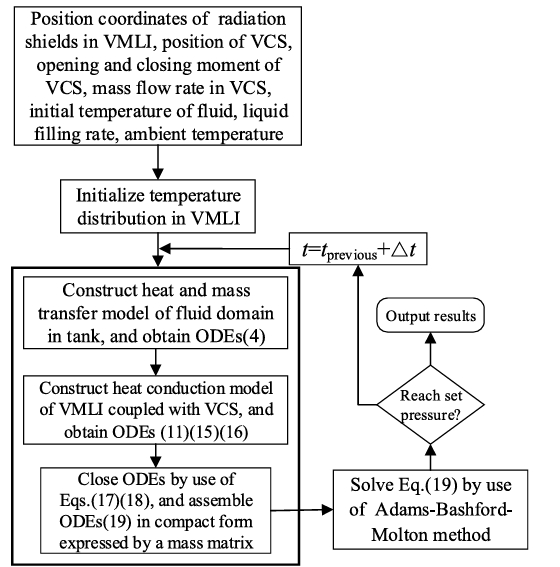

VMLI耦合VCS热传导模型

- 内层

- 中间层区

- 外层

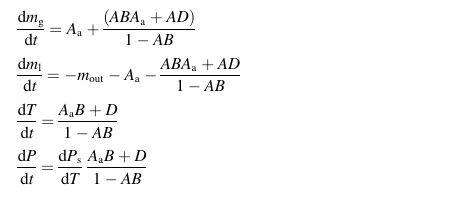

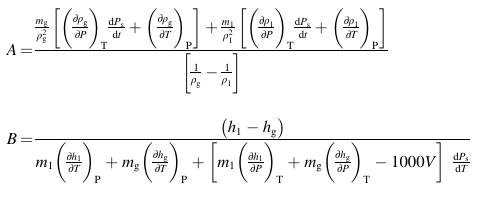

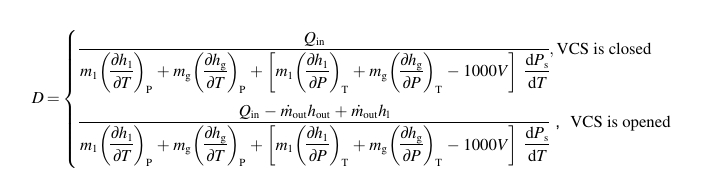

计算方法

使用矩阵简化微分方程组

MATLAB: Adams-Bashford-Moulton method

计算结果

模型验证

- 和NASA稳态模型比对(VMLI-VCS温度稳态)

- 和NASA Hastings等人的文章比对无VMLI的传热传质模型结果,该实验存在质量流失和气液混合(thermodynamic vent system)

- 质能守恒分析

评估标准

SVCS结果分析

稳态与瞬态模型对比

- 稳态:

SVCS相对坐标为0.511时,漏热量有最小值() - 瞬态:(相同运行时间范围)

SVCS相对坐标为0.622时,最大,该极值点位置与 取值无关,且在 时取得最大值0.413

但时,效率因子 最大

流率对休眠时间影响

控制

流率对储罐气液质量的影响

(相同

氢气质量

再次验证休眠时间存在极大值点

SVCS启动时刻对休眠时间影响

SVCS坐标过大,则

DVCS结果分析

最优坐标分析

随

相同

和SVCS对比分析

- 储液区压力、温度DVCS随时间上升更慢

- 储液区漏热量DVCS随时间增加更慢,且中间时间增加较缓

- VMLI区漏热量几乎重合

- VMLI区温度分布DVCS更缓升

流率及启动时刻影响

- 同SVCS,流率较小时,

存在极大值,DVCS和SVCS极大值点几乎一致 - 相同流率,启动时刻的极值点:DVCS在SVCS的右侧,即更晚启动DVCS可使得

达到极大值

Transient thermal behavior of multi-layer insulation coupled with vapor cooled shield used for liquid hydrogen storage tank

类别:

Insulation System; VMLI; VCS

- Cunnington 计算得出液氢蒸发率与总体熵增成比例(entropy-production-method)

- Chato et al. 认为实际应用最大冷屏数为3

- Seo et al. 利用一维模型认为DVCS串联效果高于并联

- Babac et al. 考虑二维热传导以及热容、热导的温度相关性,认为SVCS降低漏热量效果更好

- novel insulation system:中空玻璃微球

计算模型

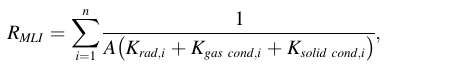

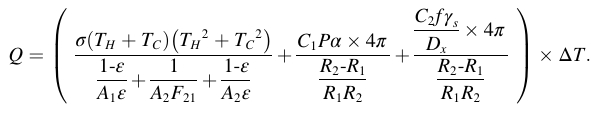

MLI传热模型

VCS传热模型

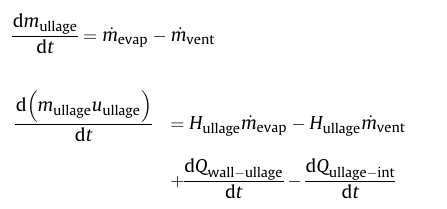

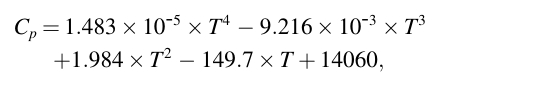

储罐液氢自增压模型

Ullage

Liquid

模型验证

计算结果

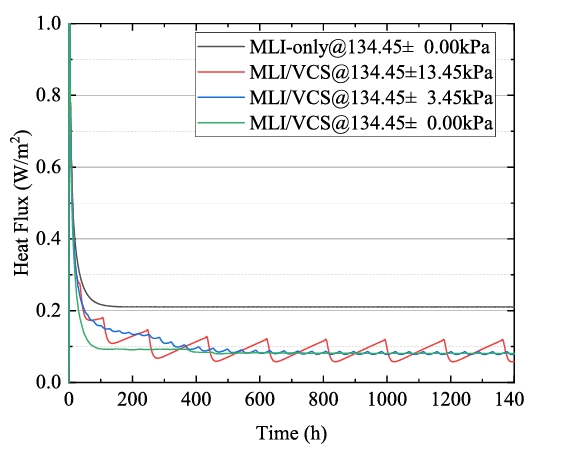

MLI有无VCS冷却比较

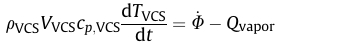

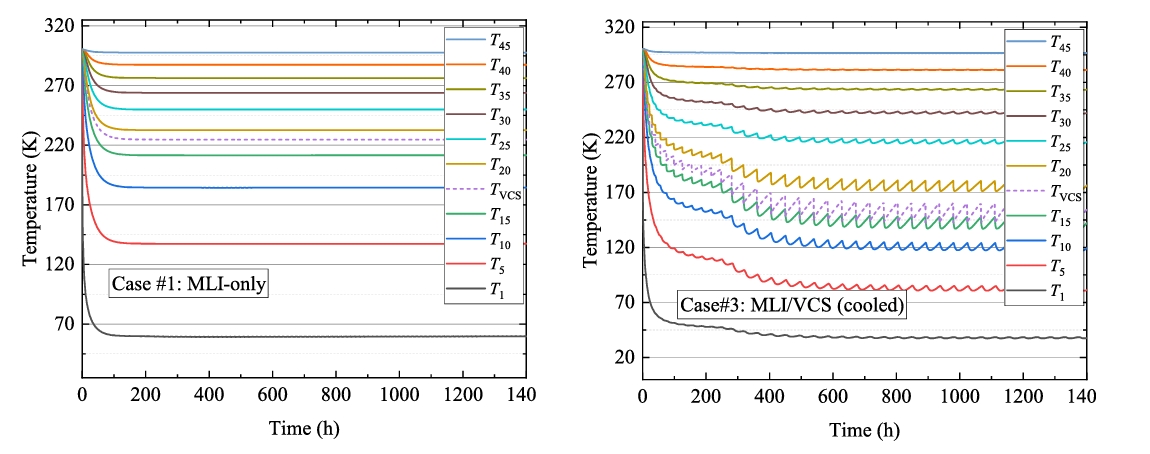

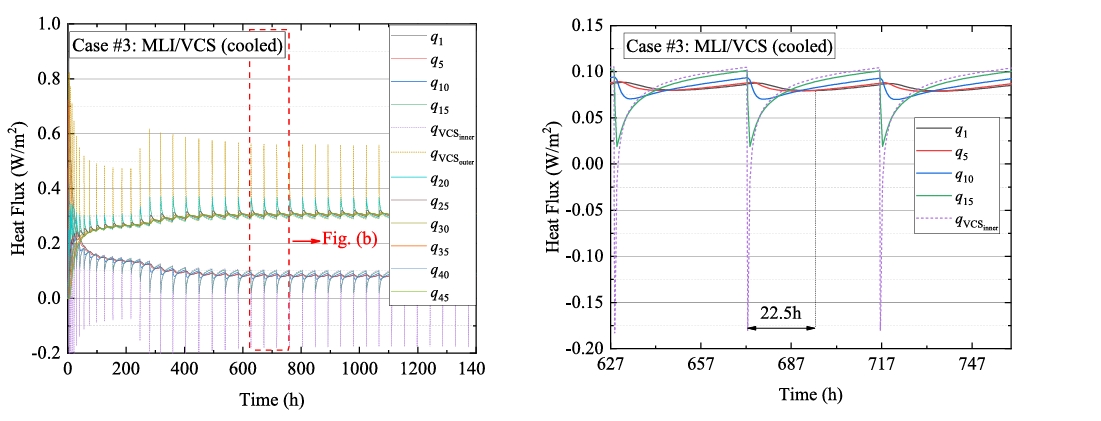

比较了纯MLI、MLI+VCS(无冷却)、MLI+VCS(有冷却)三种情形,其中MLI+VCS(有冷却)情形下达到热平衡时间较MLI+VCS(无冷却)更快,且会在平衡之后发生同频热振荡(各层温度振幅不同,越靠近VCS振幅越大)

MLI+VCS(无冷却)对时均温度无影响,但MLI+VCS(有冷却)显著降低时均温度,且在VCS处温度-位置导数不连续

瞬态绝热层漏热变化

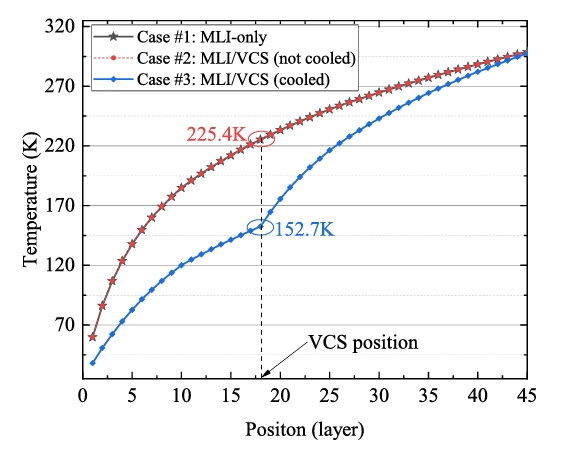

有VCS但无冷却情况下(若使用DVCS),由于VCS本身热容很高,因此内侧VCS初热通量较高,外侧初热通量较低,两者之间存在热通量差;内外侧平衡平均漏热趋于相同,则内外层VCS热通量随时间投影面积之差则为VCS提供的冷量。

有VCS但有冷却情况下(若使用DVCS),类比温度振荡,发生热通振荡,内外层镜像分布。越靠近中间层,振幅越大。且内层准平衡平均漏热小于外层。

由于VCS优良的隔热效果,致使内侧VCS漏热量相位超前第一层冷屏漏热22.5h(接近半个周期)

压力控制带对绝热效果的影响

压力控制带越窄,则温度振幅越小、漏热振幅越小

Q1:为什么vcs在中间位置冷却效果最好

Q2:为什么在VCS冷却后MLI不同位置热平衡时会发生温度振荡

Numerical modeling and optimization of thermal insulation for liquid hydrogen storage tanks

类别:

Insulation System; VMLI; VCS

本文考虑了大型液氢储罐真空度较小,残余气体液化的情况

模型建立

优化结构:

固体绝缘层+MLI+MLI

热阻分析

固体绝缘层

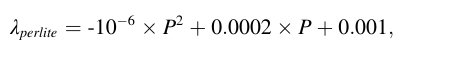

使用珍珠岩:低热容、低成本,不考虑辐射传热

MLI

VCS

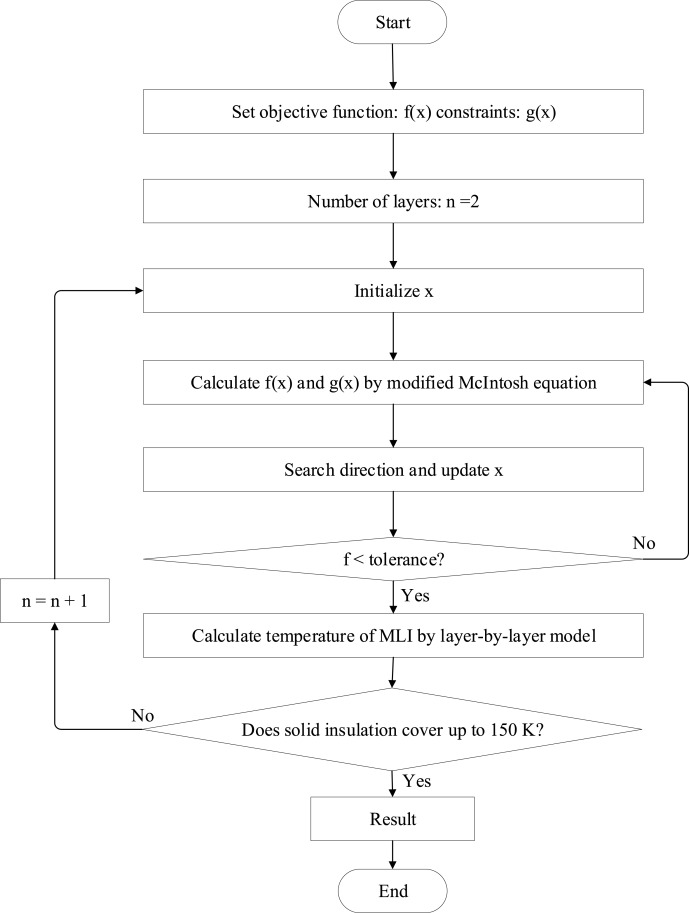

优化计算

假设

- 储罐恒温

- 各层间真空度恒定

- VCS流动不考虑

- VCS厚度认为与MLI某层相同

优化McIntosh公式

- McIntosh公式:一种用于计算整个MLI系统传热的公式

优化后:

将McIntosh方程中缺乏面积项的局限性进行了修改,将原方程中的半径项集成进去,从而能够计算出考虑体积的热流量。这种增强的方法可以应用于各种不同几何形状的储罐,不仅限于球形储罐。

对于传导和对流项,根据傅里叶定律进行了修改,将半径项引入其中,从而能够根据储罐体积计算热流量。

对于辐射项,引入了视因子的概念,以反映储罐的几何形状

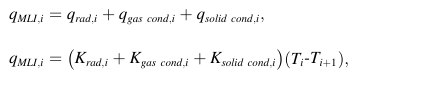

Layer-by-layer model

“Layer-by-layer model”是一种用于计算多层绝热材料(MLI)热流量的模型 。该模型可以计算出每一层MLI的温度和热流量,从而实现对MLI的优化,包括确定最佳的VCS位置和MLI层数 。

具体来说,该模型采用McIntosh方程来计算辐射、对流和传导等热流量项,并将其应用于每一层MLI,从而得到整个MLI系统的热流量 。这种分层计算的方法可以更精确地分析MLI的性能,为优化MLI提供依据

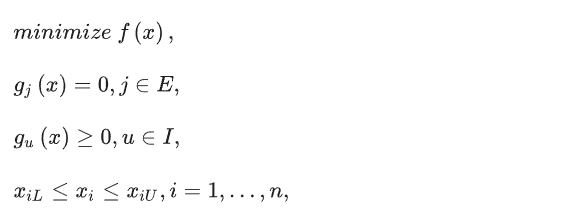

SLSQP 算法

Scalar function

constraints

计算结果

- 不同真空压力下绝热层厚度压缩率

- Perlite/Perlite+MLI/Perlite+MLI+VCS下的绝热层厚度压缩率

与仅使用perlite绝热的方案相比,采用MLI和VCS的组合绝热方案可以使绝热层厚度减少30%-50%,随着真空度的提高,两者的差异会减小。

在较高真空度下,VCS的性能优于MLI,即使在低真空度下,VCS的层数也可以大幅减少。因此即使在低真空度下,采用VCS也是合理的。

- 敏感性分析

分析了不同储罐体积(半径)下的绝热层厚度,发现绝热层厚度随储罐体积的变化趋势基本保持不变

总结

标题:numerical simulation in thermal behaviors of Multi-Insulation for LH2 storage

Liquid hydrogen is renowned for its high energy density and clean combustion product, which allow it to become the most efficient and promising fuel, especailly in space exploration and common vehicles transportation. Howerver, due to its low existing temperature, it will rapidly boil off for its temperature is rather lower than ambient temperature. Thus how to reach zero boil-off in liquid hydrogen storage is of great importance in nowadays work. One way to maintain the temperature in order to prevent boil-off is the utilization of multi-insulation in storage tank.

multi-insulation is kind of cryogenic insulation material. The most often used form is varied-density vacuum multi-insulation(VD-VMLI). MLI takes effect in lower the speed of pressurization and temperature rising process in fluid domain and leak heat from outer to inner. Within the MLI the temperature distribution changes with different structure and materials.

Some previous works have given the numerical simulation results of those process above. According to different main object, analysis are sorted into steady-state process and transient-state process.

For a certain thermal-insulation process, both steady and transient process has the same boundary condition, the only difference lies on whether considering variables changing with time or period.

It is without doubt that transient analysis is of more representative to practical situation.Although most previous work focus on steady-state analysis, recently more and more analyses of transient-state have merged.

稳态模型主要用来反应整个储罐容器的热状态分布,包括绝热层中的温度分布以及漏热量分布情况;而瞬态模型主要用来反应储液区或绝热层热状态随时间变化的情况,可分为短时间尺度(以小时为分度单位)和长时间尺度(以天数为分度单位)。

先前的大多数实验以及模拟研究主要局限于稳态假设,而涉及瞬态假设的研究也主要局限于短时间尺度情形,对于长时间尺度的研究仍然较少。

稳态模型常使用的算法为Layer-by-layer model,能有效地对多层绝热材料各层的热状态分布情况进行计算;对于整个绝热层进行模拟计算也有研究者提出相应的算法,例如SLSQP algorithm。

瞬态模型常常考虑MLI不同层之间热状态函数随时间变化趋势的异同性,以及储液区内的各状态参数随时间的变化情况,常常采取的流程是:设定初始状态参数、通过控制方程计算得到该时间节点下的其他参数、比较是否达到临界值、循环计算直至达到临界参数值、输出整个时间内的状态变化情况。

对于稳态模型,由于实验数据较多,且模型较为简单,因此现已有较为精确的计算模型。稳态模型下的热力学行为分布主要为:

- MLI中的各层温度分布情况

- MLI中的各层漏热分布情况

- 不同外部温度下的总漏热变化

- 不同漏热下的蒸发率变化

对于瞬态模型,由于实验难度较高,数据较少,因此许多热力学状态参数变化只能通过数值模拟研究获取,其研究范围主要为

- 储液区温度、压力、气液两相质量随时间变化情况

- MLI各层温度、漏热随时间变化情况

For MLI, there are many methods help to enchance its thermal performance, such as vapor-cooling shield(VCS).此外,不同真空度、不同层密度以及different spacer and radiation shield也对MLI的绝热效果有影响,因此可以改变更多的自变量来探究上述热状态参数的变化情况,如改变VCS在MLI中的相对位置、改变VCS中的蒸气流率、改变各层间的真空压力、使用不同材料以及使用不同组合的绝热材料来研究热状态参数的变化情况。

另外,除了使用储罐本身的热力学状态参数来表征材料绝热效果与液氢储存效果,也可以提出一些新的指标来表征液氢储存效果,如Ke Li等人在文章中使用蒸气消耗因子、休眠延长因子来表征相同VCS蒸气消耗情况下,储罐压力达到临界压力所用时间延长情况。这些表征参数取决于研究探究目标不同而不同。

MLI耦合VCS后主要的热状态参数变化分布研究结果:

稳态模型:

- 使用VCS前后MLI中的各层温度分布情况

- 使用VCS前后MLI中的各层漏热分布情况

- VCS在不同位置下的蒸发率变化情况

瞬态模型:

- 使用VCS前后储液区温度、压力、气液两相质量随时间变化情况

- 使用VCS前后MLI各层温度、漏热随时间变化情况

- VCS在不同位置下的休眠时间变化情况

尽管MLI耦合VCS能够有效的增强其绝热效能,包括使用多冷屏绝热系统等,但实际工程中绝热材料还会涉及材料受应力发生应变、真空度不足以致中间层残余气体液化等情况,目前仍需要结合实际问题进一步进行模拟分析。此外一些其他的低温绝热方法如真空玻璃微球等也具有良好的绝热效能,这些绝热技术亟待进一步模拟验证。

Title: Numerical Simulation of Thermal Behaviors in Multi-Insulation for LH2 Storage

Introduction:

Liquid Hydrogen (LH2) Advantages:

Liquid hydrogen (LH2) is renowned for its high energy density and clean combustion product, making it an exceptionally efficient and promising fuel. Its applications are particularly critical in fields such as space exploration and common vehicle transportation, where efficiency and performance are paramount. The high energy density of LH2 allows for longer missions and extended travel ranges, while its clean combustion contributes to reducing the environmental impact.Challenges:

Despite its advantages, LH2 poses significant storage challenges due to its extremely low boiling point. At standard atmospheric pressure, LH2 boils at approximately -253°C (-423°F). This means that without proper insulation, it will rapidly evaporate when exposed to ambient temperatures. Therefore, achieving zero boil-off in LH2 storage is essential to maintain efficiency and reduce losses. This requires advanced insulation techniques to ensure that the hydrogen remains in its liquid state over extended periods.

Multi-Insulation (MLI) Overview:

Purpose of MLI:

Multi-insulation (MLI) is specifically designed to prevent the boil-off of LH2 by maintaining low temperatures within storage tanks. MLI acts as a barrier, significantly reducing heat transfer from the external environment to the LH2. The most commonly used cryogenic insulation material in this context is varied-density vacuum multi-insulation (VD-VMLI), which provides effective thermal protection through multiple layers of insulating materials and vacuum spaces.Function of MLI:

MLI serves a crucial role in lowering the rate of pressurization and temperature increase within the fluid domain of the storage tank. It minimizes heat leakage from the outer tank to the inner tank, thereby maintaining the necessary low temperatures to keep LH2 in its liquid state. The temperature distribution within MLI varies depending on the specific structures and materials used, and understanding these variations is key to optimizing the insulation’s performance.

Numerical Simulation Studies:

Types of Analysis:

Numerical simulation studies of MLI can be broadly categorized into steady-state and transient-state processes. Steady-state analysis focuses on understanding the overall thermal state distribution within the storage system, including the temperature and heat leakage distribution across the insulation layers. In contrast, transient-state analysis examines how these thermal states change over time, offering insights into the dynamics of temperature, pressure, and phase mass variations within the storage area. Transient analysis is particularly valuable for capturing real-world operating conditions, which often involve time-dependent changes.Steady-State Model:

The steady-state model typically employs a layer-by-layer approach to calculate the thermal state distribution across each layer of the multi-insulation material. This method allows for detailed analysis of temperature and heat flux within the insulation system. Additionally, algorithms such as the Sequential Least Squares Quadratic Programming (SLSQP) are used to simulate the entire insulation layer’s thermal performance, providing comprehensive insights into how different factors affect the system’s steady-state behavior.Transient-State Model:

The transient-state model is designed to consider the time-varying thermal states within the MLI layers. This model analyzes how temperature, pressure, and phase mass in the storage area evolve over time. The procedure involves setting initial state parameters, using control equations to calculate parameters at specific time nodes, and iterating until critical values are reached. The output provides a dynamic view of how the thermal states change, which is essential for understanding the behavior of LH2 storage systems under various operating conditions.Steady-State Analysis:

Steady-state analysis provides detailed information on temperature distribution across the MLI layers, revealing how different layers interact thermally. It also examines the heat leakage distribution within the insulation layers, identifying areas where thermal efficiency can be improved. Furthermore, this analysis evaluates how total heat leakage varies with different external temperatures, offering insights into the insulation’s effectiveness under various environmental conditions. Changes in evaporation rates with varying heat leakage rates are also studied, helping to optimize the insulation design for minimal LH2 loss.Transient-State Analysis:

Transient-state analysis focuses on time-dependent changes in the storage area’s thermal states. This includes monitoring temperature, pressure, and gas-liquid phase mass over time, providing a comprehensive view of the dynamic behavior of the storage system. Additionally, it analyzes how temperature and heat leakage in MLI layers vary over time, which is crucial for understanding the long-term performance and reliability of the insulation system. These insights are particularly valuable for designing storage systems that can maintain their efficiency over extended periods.

Enhancing Thermal Performance:

Methods:

Several methods can be employed to enhance the thermal performance of MLI. One effective approach is the use of a vapor-cooling shield (VCS), which improves the overall insulation by providing additional cooling. Other factors, such as varying vacuum levels, layer densities, spacers, and radiation shields, also play a significant role in determining the insulation’s effectiveness. By varying these parameters, researchers can study how different configurations impact thermal state changes and optimize the insulation design accordingly.New Metrics for LH2 Storage Effectiveness:

In addition to traditional metrics, new indicators have been proposed to measure the effectiveness of LH2 storage. For example, the vapor consumption factor and dormancy extension factor provide insights into how long the storage tank can maintain low temperatures and pressure levels under specific conditions. These metrics are crucial for comparing the performance of different insulation designs and identifying the most efficient solutions for LH2 storage.

MLI Coupled with VCS:

Steady-State Model Results:

When MLI is coupled with a VCS, the steady-state model results show significant improvements in thermal performance. The temperature distribution across the MLI layers before and after implementing VCS reveals how the additional cooling affects each layer. Heat leakage distribution is also analyzed, showing reductions in heat transfer with the use of VCS. Furthermore, the evaporation rate variations with VCS positioned in different locations are studied, providing insights into the optimal placement of the cooling shield for maximum efficiency.Transient-State Model Results:

The transient-state model results for MLI coupled with VCS highlight time-dependent improvements in the storage system’s thermal behavior. Changes in temperature, pressure, and gas-liquid phase mass in the storage area before and after implementing VCS are closely monitored. Additionally, the temperature and heat leakage variations across the MLI layers over time are analyzed, showing how the cooling shield enhances long-term performance. Dormancy time variations with VCS in different positions are also examined, indicating how the cooling shield extends the period before critical pressure levels are reached.

Future Directions:

Challenges in Practical Applications:

While MLI coupled with VCS offers significant benefits, practical challenges remain. Material strain under stress conditions can affect the long-term durability of the insulation. Additionally, insufficient vacuum levels can lead to the liquefaction of residual gases in intermediate layers, compromising the insulation’s effectiveness. These challenges highlight the need for further research and simulation to develop robust solutions that can withstand real-world conditions.Alternative Cryogenic Insulation Methods:

Beyond traditional MLI and VCS, alternative cryogenic insulation methods such as vacuum glass microspheres show promising performance. These materials offer excellent thermal insulation properties and could provide new avenues for enhancing LH2 storage efficiency. Further simulation validation and experimental studies are necessary to fully understand and optimize these innovative insulation technologies for practical applications.

中文翻译

标题:液氢储存多层绝热的热行为数值模拟

简介:

液氢(LH2)的优势:

液氢(LH2)以其高能量密度和清洁的燃烧产物闻名,使其成为一种极其高效和有前途的燃料。它在太空探索和车辆运输等领域尤为重要,因为这些领域对效率和性能的要求非常高。液氢的高能量密度允许更长的任务时间和更远的行驶距离,而其清洁的燃烧有助于减少环境影响。挑战:

尽管具有这些优势,液氢的储存面临显著的挑战,因为它的沸点极低。在标准大气压下,液氢的沸点约为-253°C(-423°F)。这意味着如果没有适当的绝热措施,液氢在暴露于环境温度时会迅速蒸发。因此,为了保持效率和减少损失,实现液氢储存的零蒸发损失至关重要。这需要先进的绝热技术,以确保液氢在长时间内保持液态。

多层绝热(MLI)概述:

MLI的目的:

多层绝热(MLI)专门设计用于通过保持低温来防止液氢的蒸发。MLI作为一种屏障,显著减少了从外部环境到液氢的热传递。在这种情况下,最常用的低温绝热材料是变密度真空多层绝热(VD-VMLI),它通过多层绝热材料和真空空间提供有效的热保护。MLI的功能:

MLI在降低储罐液体域内的增压和温度上升速度方面起着至关重要的作用。它最大限度地减少了从外储罐到内储罐的热泄漏,从而保持液氢的低温状态。MLI内的温度分布因使用的具体结构和材料而异,了解这些变化对于优化绝热性能至关重要。

数值模拟研究:

分析类型:

MLI的数值模拟研究大致可以分为稳态和瞬态过程。稳态分析侧重于了解储存系统内的整体热状态分布,包括绝热层内的温度和热泄漏分布。相比之下,瞬态分析则研究这些热状态随时间的变化,提供储存区域内温度、压力和相质量变化的动态视图。瞬态分析尤其有价值,因为它能够捕捉实际操作条件下的时间依赖性变化。稳态模型:

稳态模型通常采用分层方法来计算多层绝热材料每一层的热状态分布。这种方法允许对绝热系统内的温度和热流进行详细分析。此外,诸如顺序最小二乘二次规划(SLSQP)等算法用于模拟整个绝热层的热性能,提供全面的见解,了解不同因素如何影响系统的稳态行为。瞬态模型:

瞬态模型旨在考虑MLI层内的时间变化热状态。该模型分析储存区域内温度、压力和相质量随时间的变化。这一过程包括设置初始状态参数,使用控制方程计算特定时间节点的参数,并迭代计算直到达到临界值。输出结果提供了热状态变化的动态视图,这对于理解液氢储存系统在各种操作条件下的行为至关重要。稳态分析:

稳态分析提供了关于MLI层温度分布的详细信息,揭示了不同层之间的热相互作用。它还分析了绝热层内的热泄漏分布,确定了需要提高热效率的区域。此外,这种分析评估了不同外部温度下的总热泄漏变化,提供了关于绝热系统在各种环境条件下有效性的见解。还研究了随着热泄漏率变化的蒸发率变化,有助于优化绝热设计以最小化液氢损失。瞬态分析:

瞬态分析侧重于储存区域内热状态的时间变化。这包括监测随时间变化的温度、压力和气液两相质量,提供储存系统动态行为的全面视图。此外,它还分析MLI层内随时间变化的温度和热泄漏情况,这对于了解绝热系统的长期性能和可靠性至关重要。这些见解对于设计能够在长时间内保持高效的储存系统特别有价值。

提高热性能的方法:

方法:

可以采用多种方法来提高MLI的热性能。一种有效的方法是使用蒸气冷却屏(VCS),通过提供额外的冷却来改善整体绝热效果。其他因素,如不同的真空度、层密度、隔离器和辐射屏,也在确定绝热效果方面起着重要作用。通过改变这些参数,研究人员可以研究不同配置如何影响热状态变化,从而优化绝热设计。液氢储存效果的新指标:

除了传统指标之外,还提出了一些新的指标来衡量液氢储存的有效性。例如,蒸气消耗因子和休眠延长因子提供了在特定条件下储罐保持低温和压力水平所需时间的见解。这些指标对于比较不同绝热设计的性能和确定最有效的液氢储存解决方案至关重要。

MLI与VCS结合:

稳态模型结果:

当MLI与VCS结合使用时,稳态模型结果显示出显著的热性能改进。MLI层在使用VCS前后的温度分布揭示了额外冷却如何影响每一层。热泄漏分布也进行了分析,显示了使用VCS后热传递的减少情况。此外,还研究了VCS在不同位置时蒸发率的变化,提供了关于最佳冷却屏位置以最大限度提高效率的见解。瞬态模型结果:

MLI与VCS结合使用的瞬态模型结果突出了储存系统热行为的时间依赖性改进。监测了在使用VCS前后储存区域内温度、压力和气液两相质量的变化。此外,还分析了使用VCS前后MLI层随时间变化的温度和热泄漏情况,显示了冷却屏如何增强长期性能。还研究了在不同位置VCS的休眠时间变化,表明冷却屏如何延长达到临界压力水平之前的时间。

未来方向:

实际应用中的挑战:

尽管MLI与VCS结合使用提供了显著的好处,但实际应用中仍然存在挑战。材料在应力条件下的变形可能影响绝热的长期耐久性。此外,不足的真空度可能导致中间层残余气体液化,降低绝热效果。这些挑战强调了进一步研究和模拟以开发能够承受实际条件的鲁棒解决方案的必要性。替代低温绝热方法:

除了传统的MLI和VCS,其他低温绝热方法如真空玻璃微球显示出良好的性能。这些材料提供了出色的热绝缘性能,可能为提高液氢储存效率提供新的途径。需要进一步的模拟验证和实验研究,以全面了解和优化这些创新的绝热技术在实际应用中的表现。

- 标题: Liquid Hydrogen Reading 1

- 作者: Little_Whale

- 创建于 : 2024-07-09 14:20:25

- 更新于 : 2024-11-19 11:01:34

- 链接: https://xlittlewhale.github.io/2024/07/09/ZBO_reading_1/

- 版权声明: 本文章采用 CC BY-NC-SA 4.0 进行许可。